Squeezing every last KPH out of the Pioneer 400...

At Helix Carbon GmbH, we’re proud to announce the arrival of our newest in-flight-adjustable propeller system: the H62A-VTL. As the direct successor to the proven H60A hub, the H62A represents the next step in our commitment to efficiency, modularity, and high-performance flight.

Designed with demanding engine platforms like the Rotax 916 series in mind, the H62A is a hydraulic, in-flight-adjustable hub that adapts in real-time to optimize performance throughout the flight envelope. For turbine and high-performance piston aircraft alike, a feathering variant of the system is available—making the H62A not just powerful, but also versatile.

Meet the H62A-VTL-3

When paired with our newest VTL blade profile—known internally as the “Talon”—the complete H62A-VTL-3 propeller assembly is a formidable performer. The VTL blades are engineered with an aggressive, high-curvature geometry that reduces noise, increases aerodynamic efficiency, and maximizes available thrust. More than just a design evolution, this blade shape allows aircraft to extract noticeably more performance from the same powerplant compared to traditional configurations.

Real-World Testing Results

Recent flight tests with the Shark Aero 600, powered by a Rotax 912ULS, have demonstrated the real-world advantages of this system. Compared to the aircraft’s OEM propeller, the H62A-VTL-3 delivered a measured improvement of around 10% in overall efficiency and cruise performance—a significant gain for operators looking to stretch range or increase useful load.

On the Pioneer 400 by Pioneer Aircraft, equipped with the Rotax 916iS, the H62A-VTL not only held its own but surpassed the performance of our own previous generation systems designed for that airframe.

Modularity Meets Performance

One of the most distinctive features of the H62A (and the related H42A series) is its modularity. Built for ease of use in the field, a qualified mechanic can install an H62A propeller in under 20 minutes. Blades can be detached easily for transport or compact storage, offering a rare blend of high-end performance and day-to-day practicality—particularly beneficial for operations with space constraints or logistical considerations.

Specs & Configuration Options

The H62A is rated for engine outputs up to 180 kW (approx. 241 HP) and can be configured with 2 to 5 blades depending on the airframe and mission profile. Both the H62A and H42A hubs are compatible with a variety of blade types, offering flexibility for future upgrades or mission-specific tuning.

Stay tuned for the full technical release of the H62A-VTL series, and in the meantime, feel free to contact us if you’re interested in test programs, compatibility assessments, or early adopter opportunities.

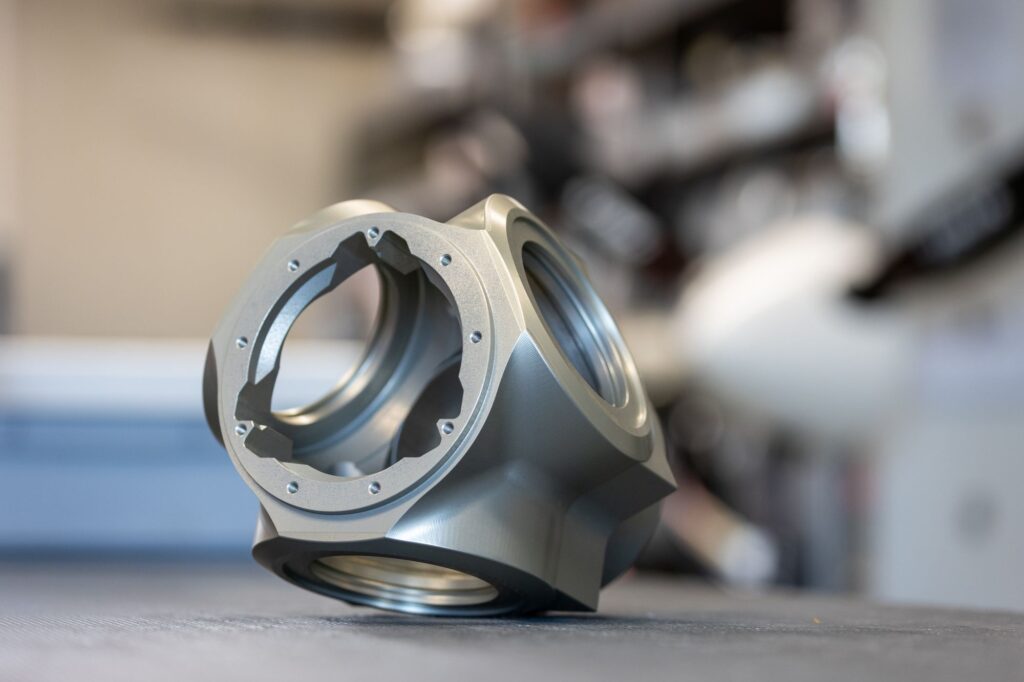

The core of the H62A propeller hub is milled from a solid aluminum billet.