Development of the ARC Propeller

Propeller Radial Curvature Classification: ARC, NRC, and TRC

Propeller performance is fundamentally governed by blade geometry, particularly the transverse sweep, or radial curvature, along the blade’s span. To precisely define and categorize the varying approaches to this design element, propeller geometries can be classified into three distinct categories based on their Radial Curvature:

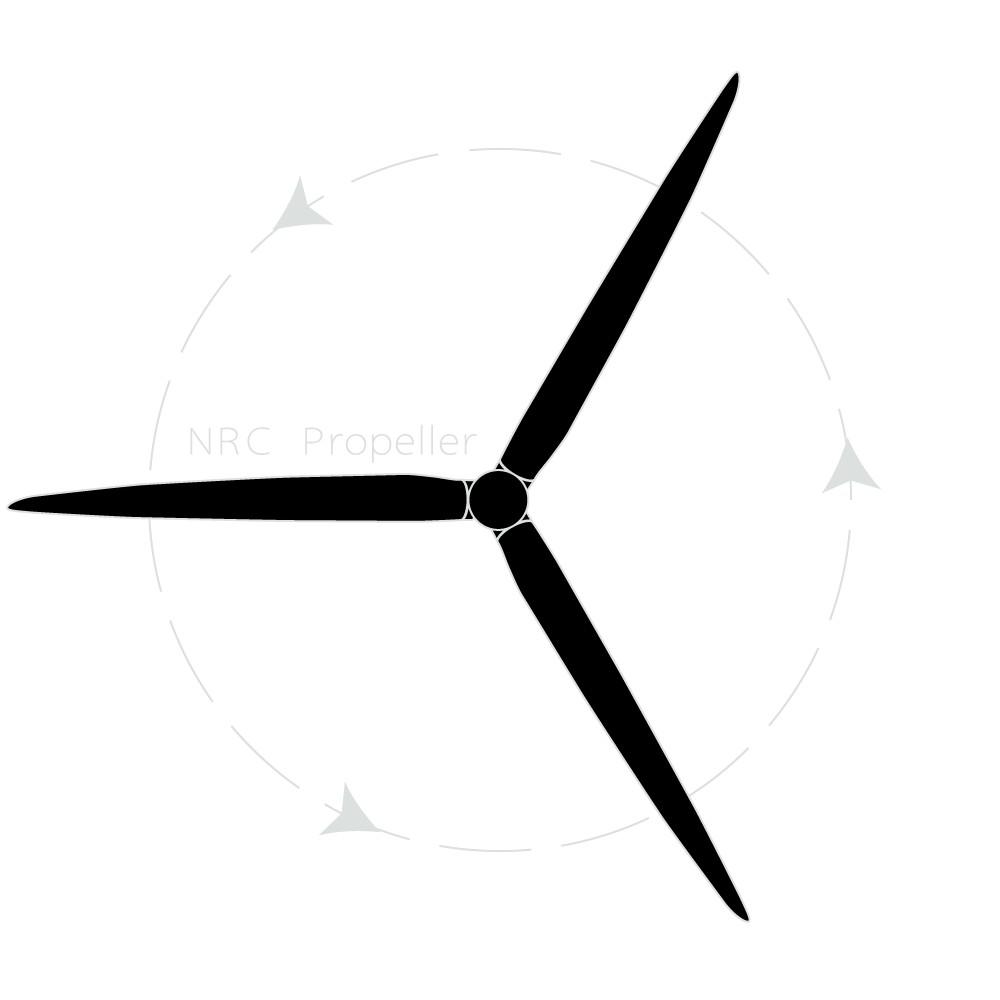

Neutral Radial Curvature / Neutral Radial Curve (NRC)

Neutral Radial Curvature (NRC) describes the most basic geometry where the blade maintains a relatively straight, linear path from the root to the tip. These propellers exhibit zero skew, meaning the blade sections are aligned without any forward or aft sweep relative to the hub’s axis. While simple to manufacture and historically common, NRC designs typically achieve peak efficiency only across a narrow range of operating conditions and are often susceptible to higher noise levels due to their abrupt interaction with the airflow.

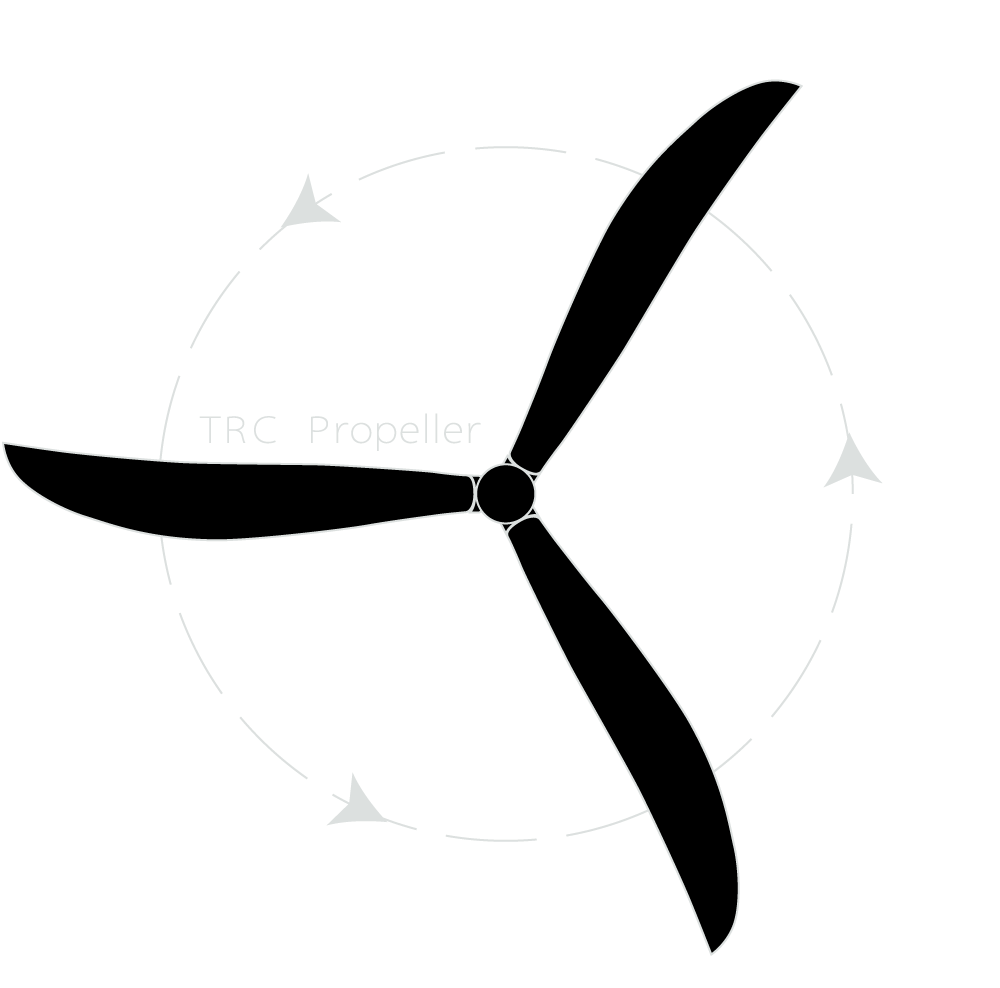

Trailing Radial Curvature / Trailing Radial Curve (TRC)

Trailing Radial Curvature (TRC) represents the dominant design across modern propeller technology, often characterized by the distinct, swept-back scimitar shape. In TRC propellers, the blade sections sweep aft or backward, trailing the direction of rotation. This geometry, technically defined as positive skew, was developed to mitigate vibration and noise by spreading the pressure field over a longer rotational arc. While TRC designs improved over NRC models, they still adhere to conventional aerodynamic limits, often sacrificing maximum potential thrust for noise and vibration management.

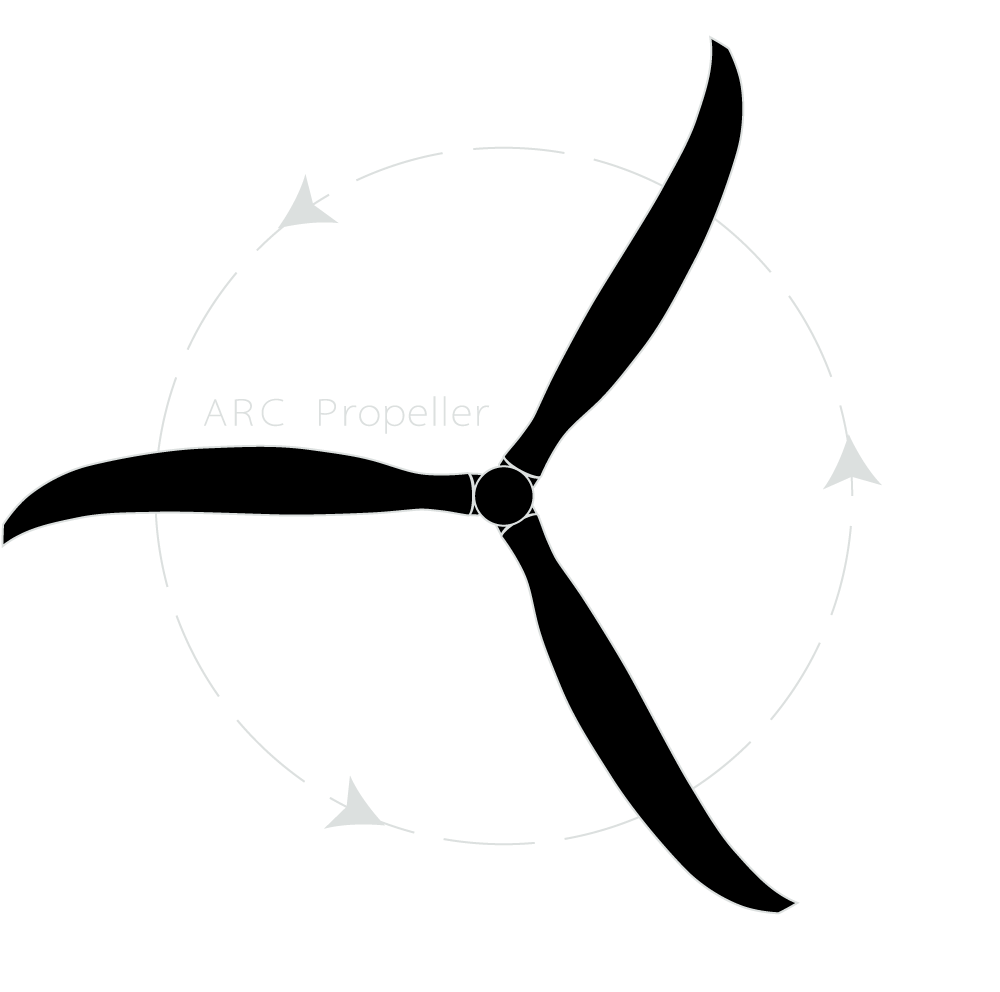

Advanced Radial Curvature / Advance Radial Curve (ARC)

Advanced Radial Curvature (ARC) defines a revolutionary propeller class where the blade intentionally sweeps forward, leading the direction of rotation. This geometry is defined by forward skew (or negative skew). The ARC principle seeks to fundamentally re-engineer the interaction between the blade and the working fluid. By advancing the curvature, the design aims to manage the shedding of tip vortices, significantly reduce the pressure pulse responsible for noise, and optimize pressure distribution across the blade. This approach is engineered to achieve a simultaneous improvement in thrust generation, acoustic performance, and overall efficiency beyond the capabilities of conventional NRC and TRC designs.

The Helix Innovation: Pioneering ARC Technology

The innovative concept of Advanced Radial Curvature (ARC) was the brainchild of Richard Krüger-Sprengel, CEO and founder of Helix. Recognizing the performance limitations inherent in traditional NRC and TRC geometries, Krüger-Sprengel and Helix began intensive research and development into the forward-swept principle in the late 2010s. The results of this initial phase led to the first market application of the technology in 2019 with the introduction of the VHL series. Early versions were rigorously validated through controlled wind tunnel testing and real-world application on demanding, smaller aircraft platforms, including trikes and paramotors.

This foundational work culminated in the 2024 release of the VTL “Talon”, which Helix identifies as its first truly optimized ARC propeller. Extensive testing has demonstrated that the VTL’s Advanced Radial Curvature geometry yields measurable gains: providing significantly greater thrust, higher propulsive efficiency, and a demonstrably quieter operational signature compared to conventional NRC and TRC propellers in the same class. Through the introduction of the ARC class, Helix has redefined the expected performance envelope for modern propellers.